Property Management

Basics

Emergency lightning:Testing requirements explained

A detailed look at the most significant cybersecurity threats this year, including practical tips and strategies to protect against them

May 2, 2025

Keywords

emergency lighting testing requirements

emergency lighting regulations UK

emergency lighting test procedure

how to test emergency lighting

UK emergency lighting compliance

landlord emergency lighting responsibilities

emergency lighting inspection checklist

emergency lighting monthly test

emergency lighting annual test

emergency lighting maintenance UK

emergency lighting standards BS 5266

how often should emergency lighting be tested UK

what is required in an emergency lighting test

emergency lighting compliance for landlords

emergency lighting tests for commercial buildings

emergency escape lighting testing guide

emergency lighting testing logbook requirements

best emergency lighting compliance software

Emergency lightning:Testing requirements explained

Did you know that UK emergency lighting rules say you must test all emergency lights monthly? This regular check will give a guarantee that these vital safety systems work perfectly at the time they're needed most.

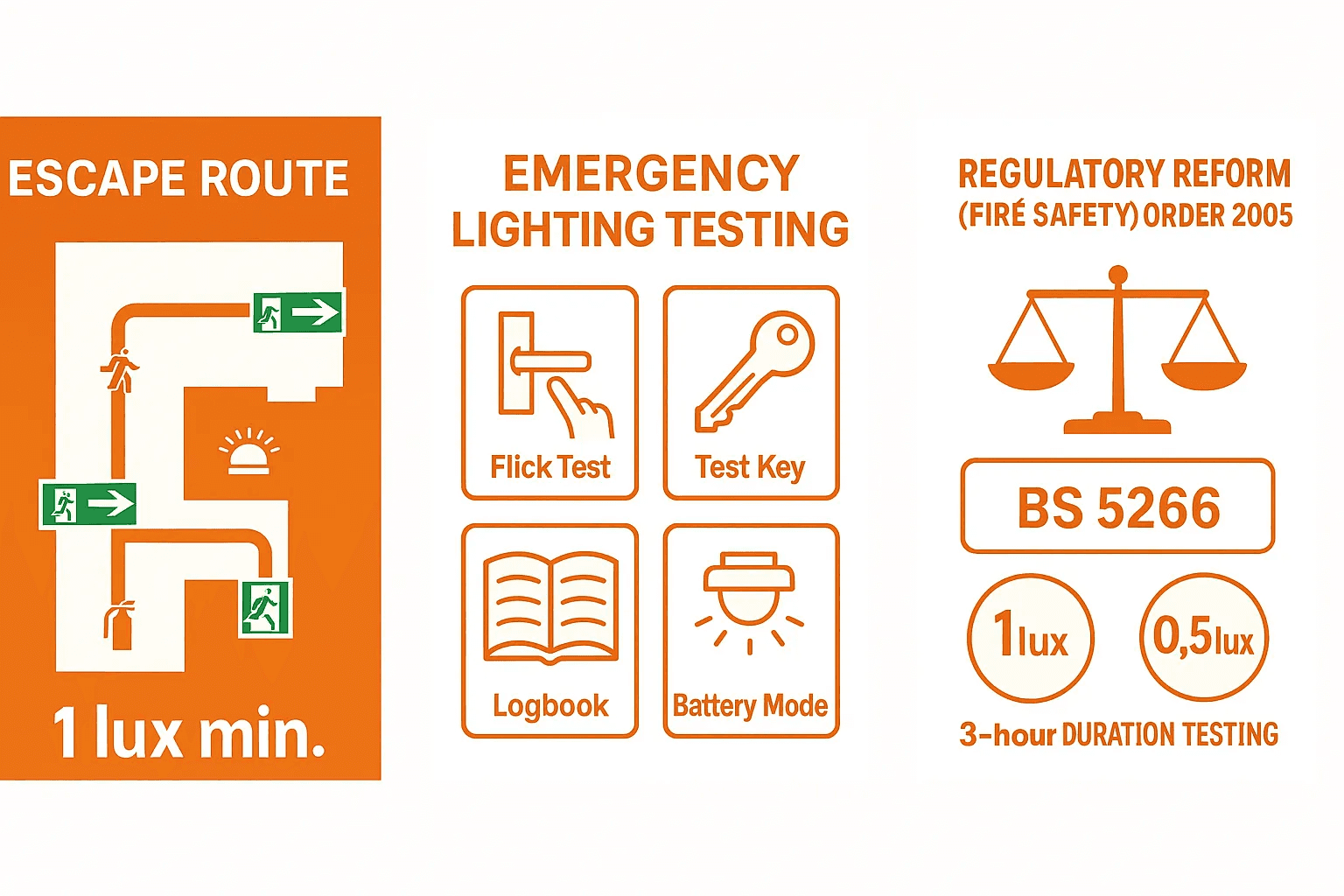

UK law requires emergency lighting in schools, hospitals, multi-storey dwellings, and all public buildings. The Regulatory Reform (Fire Safety) Order 2005 states that businesses need proper emergency escape lighting. This includes offices, factories, entertainment venues, and even temporary structures like tents and marquees. British Standard 5266 provides a complete set of emergency lighting testing requirements. Building owners can choose from four testing methods: manual test, self-test, wireless addressable test, and wired DALI addressable test.

This piece covers everything about emergency lighting rules and testing requirements. You'll learn about the legal framework, testing schedules, and documentation you need. We've also included practical tips to help keep your property in line with current UK standards.

Understanding Emergency Lighting Regulations in the UK

UK emergency lighting rules combine various laws and standards to keep building occupants safe. Building owners and managers who know these rules can set up the right systems and avoid legal troubles.

Legal framework: Building Regulations and Fire Safety Order

The Regulatory Reform (Fire Safety) Order 2005 is the life-blood of UK emergency lighting requirements. This law applies to all buildings except private homes and creates a complete safety framework with legal authority. Article 14(2)(h) of the Order states that "emergency routes and exits requiring illumination must be provided with emergency lighting of adequate intensity in the case of failure of their normal lighting".

The Order names a "responsible person" – usually the employer, building owner, or occupier – who must follow these regulations. This person needs to assess risks and keep emergency lighting systems working properly throughout the building's life. Breaking these rules can lead to heavy penalties. Some landlords face fines up to £400,000 or jail time for serious violations.

Other laws that support these requirements include:

Building Regulations 2000 (defining room sizes requiring emergency lighting)

Workplace Directive 89/654

Management of Health and Safety at Work Regulations 1999

The Signs Directive (implemented via Statutory Instrument 341)

BS 5266 emergency lighting regulations explained

British Standard 5266-1 gives detailed technical guidelines for designing, installing, maintaining, and testing emergency lighting. This standard works with other BS, BS EN, BS EN ISO, IEC, and BS ISO standards.

BS 5266 sets minimum lighting levels: 1 lux for escape routes (measured at floor level), 0.5 lux for open areas, and at least 10% of normal lighting for high-risk task areas. Emergency lights must work for three hours during power failures. A one-hour duration works for buildings that people evacuate right away and don't reenter until batteries recharge fully.

The standard tells you where to put emergency lights. You need them near exits, stairs, level changes, fire equipment, first aid posts, and along escape routes. These technical rules help turn legal compliance into real-life safety.

Landlord responsibilities and commercial obligations

Landlords have different emergency lighting duties based on property type. Houses in Multiple Occupation (HMOs) have requirements that change with building size and occupancy. HMOs with five or more occupants must have emergency lighting in all shared areas to get mandatory licenses.

Commercial property owners have wider duties. The law requires emergency lighting in all non-residential buildings where the public enters or where people work. This includes offices, shops, care facilities, community halls, entertainment venues, schools, hotels, factories, and warehouses.

Building owners and managers must:

Get qualified professionals to install systems

Test systems regularly (monthly functional tests and yearly full-duration tests)

Keep all records including installation certificates, maintenance logs, and compliance certificates

Choose a qualified person to manage the emergency lighting schedule

UK emergency lighting rules create a resilient system that protects occupants and clearly defines what property owners and managers must do.

Emergency Lighting Testing Requirements and Frequency

Testing emergency lighting systems isn't optional—it's a vital requirement to make sure these life-saving installations work when real emergencies happen. BS 5266 sets a well-laid-out testing schedule that building owners must follow to comply with UK regulations.

Monthly testing: what is required

Monthly functional tests are the foundations of any emergency lighting maintenance program. These quick assessments, often called "flick tests," simulate a power failure briefly to check if each emergency light works properly.

Manual testing systems just need a key-switch (commonly called a "fish key") to disconnect the permanent live supply from each fitting. The emergency light should switch to battery operation right away once disconnected. Some fittings come with built-in test buttons that work the same way.

The monthly check should:

Make sure all luminaires and signs light up correctly

Check if indicators work properly

Find units that need maintenance

Stay brief to save battery life

In spite of that, you should test long enough to get a full picture—usually 30 seconds to one minute. Once normal power returns, it's significant to check if charging indicators show batteries are recharging.

Annual full-duration test explained

Beyond monthly checks, BS 5266 requires a detailed annual test that redefines the limits of emergency lighting systems. This full-duration check means running the whole system on battery power for its full rated time—usually three hours.

This extended test makes sure that:

Batteries keep enough capacity throughout their rated duration

Light levels stay adequate even after long operation

All parts work reliably during extended use

The three-hour test can disrupt operations, so experts suggest scheduling these checks during low-risk periods or when buildings are empty. On top of that, it takes time for batteries to fully recharge—usually 24 hours.

Emergency lighting testing logbook requirements

Good documentation is the legal foundation of emergency lighting compliance. BS 5266 specifically requires keeping a detailed logbook to prove regular testing happens.

A proper emergency lighting logbook must have:

Installation details and commissioning certificate

Records of all monthly and annual tests

Specific dates, times, and test durations

The person's name who did each check

Details about any failures found and fixes made

You should keep these records for at least three years to show ongoing compliance. Note that building owners could face legal issues if they don't keep proper records, whatever the system's actual condition.

Who can carry out the tests?

"Competent person" appears often in emergency lighting rules, but what does this mean? A trained responsible person on site—either staff members or outside contractors—can do monthly testing.

The annual duration tests need more specialized knowledge. Someone with relevant training, qualifications, and experience in emergency lighting systems should do these detailed assessments. They must understand BS 5266 standards and testing protocols.

Most organizations let qualified electrical contractors or certified fire safety engineers handle annual testing. This choice ensures compliance and reduces liability risks from incorrect testing procedures.

Recommended Testing Procedures by Experts

Fire safety experts support a structured approach that goes beyond minimum compliance standards for emergency lighting tests. Their best practices ensure these life-saving systems work without fail in real emergencies.

Daily checks for central battery systems

Buildings with central battery emergency lighting systems need daily visual inspections. Central systems power multiple emergency lights from one location, unlike self-contained units where each light has its own battery. These daily checks look at the central panel indicators to verify system status.

A proper daily inspection includes:

Checking that all "system healthy" indicators light up

Making sure no fault lights appear on the control panel

Recording any problems in the maintenance logbook

Buildings with individual battery units in each emergency light—the most common setup—don't need daily checks. Notwithstanding that, some safety professionals support quick visual inspections to spot obvious damage or blockages.

Monthly simulation of power failure

Monthly functional tests are the life-blood of good emergency lighting maintenance. These brief power interruptions, often called "flick tests," confirm that all units activate correctly during an outage.

The process works this way:

Cut off the mains power supply to simulate an electrical failure

Check each emergency light lights up within five seconds

Look at all units for damage, cleanliness and correct positioning

Check that exit signs stay visible with directional arrows pointing the right way

Write down results in your emergency lighting logbook

Emergency lighting systems feature several specialized types. Each type tackles specific safety needs when power fails or emergencies strike. Building owners who understand these differences can implement solutions that line up with BS 5266 requirements more effectively.

Escape route lighting

The foundation of any emergency lighting system starts with escape route lighting. These fixtures light up designated evacuation pathways and guide occupants safely out of the building. The system highlights critical safety equipment like fire extinguishers, first aid stations, and emergency exit keys. BS 5266 requires a minimum illumination level of 1 lux measured at floor level for all escape routes. The positioning of escape lighting must clearly show direction changes, stairways, and level changes. This careful placement prevents trips or falls during evacuation.

High-risk task area lighting

Safety requirements become more demanding in areas with potentially dangerous processes. High-risk task area lighting meets these challenges. These specialized fixtures turn on within 0.5 seconds of power failure. They provide at least 10% of normal illumination levels, never dropping below 15 lux. To name just one example, see workshops with machinery, laboratories with hazardous materials, or control rooms running essential systems. This lighting helps operators shut down equipment safely before they evacuate. Unlike standard emergency lighting, these installations focus on specific workstations or equipment rather than general pathways.

Maintained vs non-maintained lighting

The difference between maintained and non-maintained lighting lies in their operation, not their function. Maintained emergency lighting stays on whatever the power status, working as both normal and emergency lighting. Theaters, cinemas, and nightclubs must have these fixtures because their lighting typically stays dimmed. Non-maintained lighting works only during power failures, which saves energy and extends component life. Many installations use switchable units that work in either mode based on the building's needs. Non-maintained systems cost less to run but require more thorough testing since you can't check their function during normal operation.

Safety lighting for vulnerable occupants

Buildings with vulnerable individuals must have better emergency lighting. Schools, hospitals, care homes, and similar facilities don't deal very well with standard systems. Their occupants might move slowly or have mobility issues. These environments must keep emergency lighting running for three hours instead of the standard one hour. Light levels must help reduce anxiety and prevent confusion that darkness might cause among vulnerable occupants. These installations typically use higher lux levels, more fixtures at lower heights, and extra directional indicators. Such comprehensive systems ensure everyone can evacuate safely.

Where and How to Install Emergency Lighting

Emergency lighting placement is a vital part of ensuring safe evacuation during power failures. BS 5266 gives detailed guidance about strategic collaborations for installing lights throughout buildings.

Key areas: stairways, exits, fire equipment zones

We installed emergency lighting near each exit door meant for emergency use. Stairways need extra attention - lights must be positioned to give direct light to each flight. This makes all inclines and declines visible. The lights must be within 2 metres of fire-fighting equipment, first aid points, and call points. This ensures these critical resources stay available. Corridor intersections, direction changes, and floor level changes also need emergency lighting.

Toilets, cubicles, and disabled access areas

Toilet facilities bigger than 8m² need emergency lighting. Disabled user toilets need emergency lights whatever their size. Multiple closet facilities without borrowed light need their own emergency light in each closet. This is different from single closet facilities under 8m², which might not need emergency lighting.

Placement of illuminated fire exit signs

Exit signs should sit 2.0m above floor level when mounted above doors or hung from ceilings, and 1.7m when placed on walls. People should see the next sign from their current position as they move along an escape route. Signs must mark every direction change, level change, and decision point.

Escape route lighting standards

BS 5266 sets minimum light levels: 1 lux for escape routes at floor level, 0.5 lux for open areas larger than 60m², and at least 10% of normal lighting for high-risk task areas. Open areas bigger than 60m² and those with escape routes running through them need emergency lighting to guide people to exits.

Conclusion

Emergency lighting isn’t just another compliance checkbox in the UK — it’s a legal responsibility backed by the Fire Safety Order and enforced through strict technical standards like BS 5266. When building owners ignore these rules, they don’t just risk fines or penalties — they gamble with people’s lives.

A fully compliant emergency lighting system is built on three pillars: correct installation, regular testing, and accurate documentation. Monthly flick tests, annual three-hour duration tests, and a complete logbook are non-negotiable. Whether it’s an office, a warehouse, an HMO, or a care facility, the responsible person must ensure that every escape route, stairway, exit sign, toilet area, and high-risk workspace has the right level of illumination during a power failure.

Buildings that take emergency lighting seriously are buildings that save lives. Following these regulations isn’t just about meeting standards — it’s about ensuring that, when the lights go out, every person in the building can find a safe way out.

Explore

Discover expert insights, tips, and updates on property compliance, safety regulations, and best practices to keep your properties secure and compliant.